AIR DRYER

Mecken Refrigeration type Dryer operates on the method of cooling the air to near freezing point to remove the moisture and the cold air is reheated by the incoming air to approximately 10°C below the incoming compressed air temperature at nominal conditions.

The Refrigeration Dryer consists of an air drying unit with centrifugal cum demister pad condensate separator and a refrigeration circuit.

The refrigeration circuit consists mainly of a compressor, a condenser, a receiver, a vapour liquid accumulator with liquid refrigerant and an evaporator.The air drying unit consists of two kinds of heat exchangers, one is air to air heat exchangers and second is refrigerant to air heat exchangers.

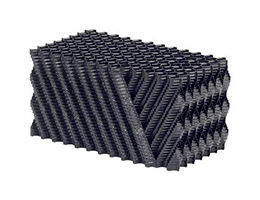

The Heart Of The System Is The Special Foamed In, Patented Heat Exchanger Which Makes It Outperform Other Dryers

The function of the air to air heat exchanger is to lower the load on the refrigerant system and secondly by warming the outgoing cold air pipelines to the required temperature.

The refrigerant to air heat exchanger(s) further cools the air to the required temperature thus condensing the water vapour from the air, which is automatically drained.

HEAT EXCHANGER

Mecken Refrigeration type Dryer operates on the method of cooling the air to near freezing point to remove the moisture and the cold air is reheated by the incoming air to approximately 10°C below the incoming compressed air temperature at nominal conditions.

The Refrigeration Dryer consists of an air drying unit with centrifugal cum demister pad condensate separator and a refrigeration circuit.

The refrigeration circuit consists mainly of a compressor, a condenser, a receiver, a vapour liquid accumulator with liquid refrigerant and an evaporator.The air drying unit consists of two kinds of heat exchangers, one is air to air heat exchangers and second is refrigerant to air heat exchangers.

HEAT EXCHANGER’S SERVICED

The function of the air to air heat exchanger is to lower the load on the refrigerant system and secondly by warming the outgoing cold air pipelines to the required temperature.

The refrigerant to air heat exchanger(s) further cools the air to the required temperature thus condensing the water vapour from the air, which is automatically drained.

PRODUCTS & SPARES

HEAT EXCHANGER

Refrigeration Air Dryer

Fills

HEAT EXCHANGER